- Olomouc

- Advantage Consulting, s.r.o.

-

Benefity:

-

-

-

-

-

-

-

-

-

-

Životopis - CV (z latinského curriculum vitae, v překladu znamená běh životem) je vaše vizitka, váš první dojem, který u potencionálního nového zaměstnavatele uděláte. Na konci článku najdete životopis zdarma ke stažení.

Klasický životopis je souhrn vašeho vzdělání, vašich pracovních zkušeností, znalostí a dovedností. Slouží budoucímu zaměstnavateli, aby se o vás dozvěděl základní informace, než si vás pozve na osobní (či virtuální) setkání. Jedná se o vaši vizitku, dokument, který je nezbytný pro získání nového zaměstnání.

| Aktuální nabídka práce |

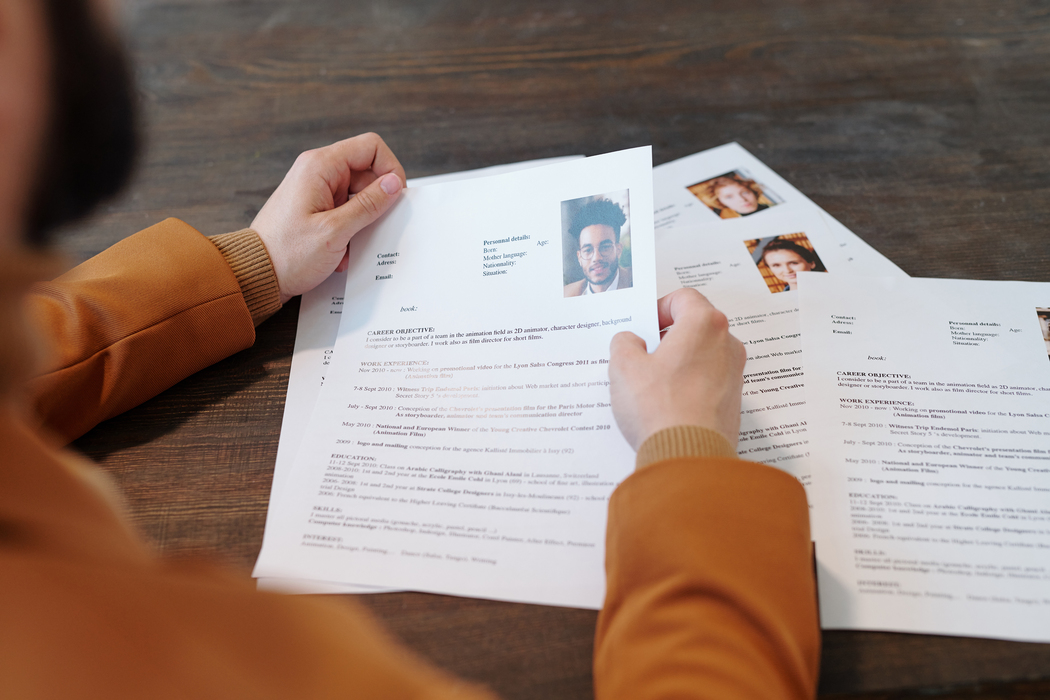

Představte si, že jste personalista a dostanete tyto dva životopisy. Který se vám líbí více?

S tímto životopisem si pan Novák moc práce nedal, mohli bychom ho nazvat nestrukturovaný životopis vzor, ukázka níže:

Pan Novák poskytl stejné informace v upraveném formátu a posílá tak do nové práce téměř vzorový životopis:

I tento druhý příklad životopisu se může vylepšit, každopádně už nyní je rozdíl velký. A pro zmíněného personalistu je jednodušší vybrat, se kterým uchazečem se setká.

Pojďme si ukázat, jak vytvořit životopis, který zaujme na první pohled nebo si sestavte životopis online během krátké chvíle a odešlete jej na některou z našich nabídek zaměstnání:

| Vytvořit životopis |

Tvorba životopisu, který bude za něco stát, zabere čas a je vhodné se nad ní pořádně zamyslet. Naše tipy a triky vám pomohou s vytvořením životopisu, který vás dostane do vysněné firmy.

Jak podrobný životopis bude, záleží na vašich znalostech a zkušenostech. Není třeba vypisovat všechny detaily, držte se základních údajů a úspěchů. Detaily můžete na vyžádání sdělit na pohovoru.

Pokud je inzerát, na který odpovídáte, v angličtině, nebo je anglická verze životopisu vyžadována, pošlete pouze požadovanou anglickou verzi životopisu.

Jak napsat životopis strukturovaný profesionální, který zaujme, mám vložit fotku, mám uvést vzdělání do životopisu, mám uvést zájmy a koníčky do životopisu? Na všechny otázky odpovíme v článku Vše o životopisu, profesní životopis vzor v češtině a angličtině zdarma.

Chcete si vytvořit moderní životopis? Jistě můžete. Jen zvažte, do jaké společnosti a na jakou pozici jej budete posílat. Do banky na pozici bankovního úředníka doporučujeme klasický strukturovaný profesní životopis. Na pozici fotografa nebo design specialisty můžete popustit uzdu své fantazii a s formou životopisu si vyhrát, s tím, že dodržíte pravidla popsaná výše.

| Aktuální nabídka práce |

Vytvoření životopisu zdarma podle předlohy či formuláře? S námi si můžete vytvořit strukturovaný životopis podle šablony ke stažení, kterou naleznete v níže uvedeném odkazu. Jedná se o formulář životopisu, který si můžete přizpůsobit. Nedáváme vám klasický strukturovaný životopis (vzor) v PDF, ale v plně editovatelné podobě.

Klasický životopis vzor / šablona ke stažení v češtině zdarma.

Klasický životopis vzor / šablona ke stažení v angličtině zdarma.

Máte připravený životopis! Už jste jen krok od toho, abyste vysněnému zaměstnavateli mohli odpovědět na jeho inzerát. Pojďme si připravit motivační dopis, který doplní váš životopis a průvodní dopis, který by neměl nikdy chybět.

Publikováno 11. dubna 2022

Pracovní portál JenPráce.cz provozuje